Before describing the structure of the hive we should ask what it is for. Clearly its main purpose is to house the bees in a safe environment where they can get on with making more bees and honey. They could do this in a hole in a tree but we want to be able to get at the honey so, as we will see, the modern hive is designed so that we can get the honey without killing the bees or seriously compromising the colony.

One of the first big improvements on the structure of the hive was the concept of the "bee space". Left to themselves bees will fill a hive with brace comb or burr comb. This is of limited use to the beekeeper though it is how bees do things naturally. The "bee space" is a space between bits of the hive which is large enough for the bees to move through but not large enough for them to want to fill with brace comb. If it were not for the bee space then the bee would be presented with a tall column of cells with no area to move from one column to another except at the bottom of the hive. The importance of this will become clearer as we discuss the structure of the hive.

The hive which I am going to describe here is based on the Langstroth Hive patented in 1852. It is not the only type of hive as there are also Top bar hives and Warre hives amongst others.

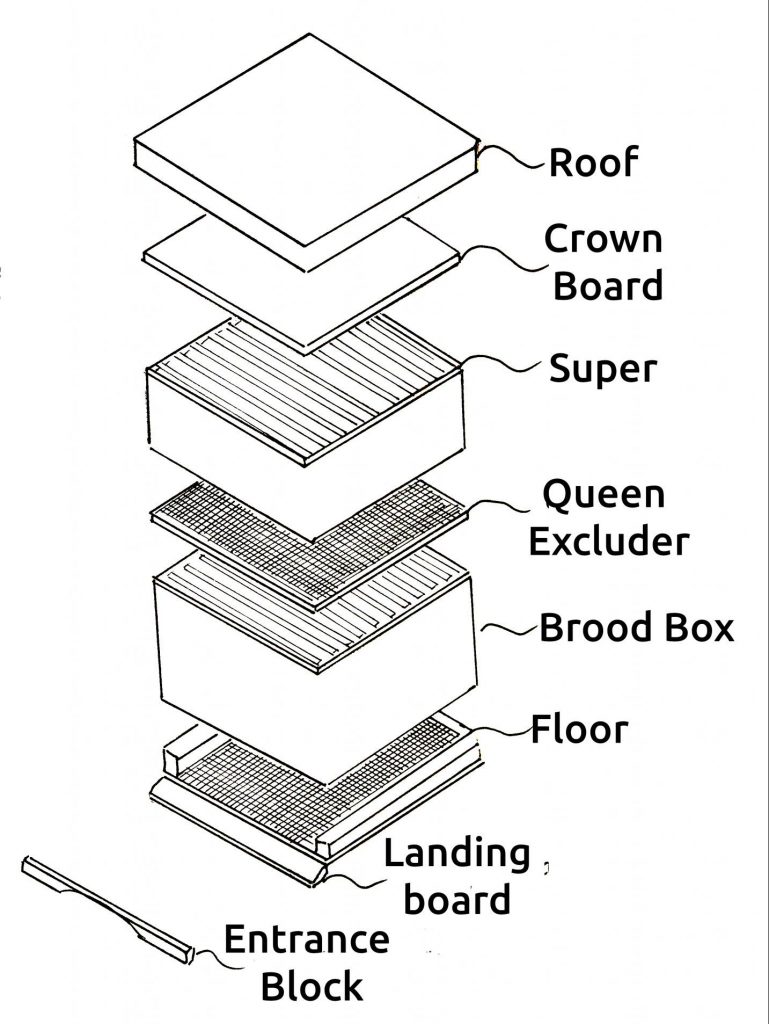

In the Langstroth Hive the frames on which the bees make cells to store brood or honey, are hung vertically in parallel. It consists of a series of boxes on top of each other.

Lid

This is the very top layer and is usually a wooden frame with a galvanised steel cover. It telescopes over the hive and on a National hive it has a internal dimension of 476 mm square and a height which varies from 114mm to 160mm. Because it is raised it allows a ventilation space above the crown board.Its purpose is to keep the rain out and trap the heat in. When doing a hive inspection the lid is the first thing to come off. I always take the lid off and turn it upside down on top of an adjacent hive or the ground to one side of the hive. Each piece of the hive I take off is then placed on the up turned lid. That way I do not put hive sections on the ground where they may pick up dirt.

Crown Board

The crown board sits just below the lid. It is just a thin sheet of wood with one or two holes in it and sits on top of the super. The purpose of the holes is that you can feed the bees through that hole in the winter. In the summer, by putting a clearing device into the holes, you can turn a crown board into a clearer board. There are some bee keepers who do not use a crown board at all. For a time I was one of those and I used a piece of hessian sacking with a hole in it. I was not convinced that it was what I wanted to do so I went back to the wooden crown board.

Super

The super is the place where the bees store the honey. There may be one or more supers on the hive depending on how productive the bees are. The super itself is no more than an empty box with a ledge on each side on which sit the frames. It is the frames where the bees store the honey.

Frames

The frames are quite simply "frames" which hold the wax on which the bees will create the cells in which to store the honey. Because the footprint of the hive is square the frames can be put so that they run acoss the hive or from front to back - assuming we are calling the entrance the front. If the frames run across the hive this is called the "warm way" as the breeze from the front door cannot blow straight to the back of the hive. If the frames run front to back then that is called the "cold way".

Queen Excluder

Before the design of the modern hive the extraction of honey meant the colony of bees would be destroyed or at least very damaged when the honey was extracted. This was because the queen lay eggs in vacant cells and the workers put honey in vacant cells so each frame in the hive would be a mix of brood and honey. Then someone, realising the queen bee was a different shape from the rest of the bees designed a screen which the workers can pass through but not the queen. Thus we can trap the queen below this screen - the queen excluder - and thus eggs and then brood are restricted to the area below the queen excluder. The workers can pass through the screen so they put honey in the vacant cells above the screen.

Brood Box

Because the queen is in the brood box this is where she lays her eggs and hence where the brood is raised. It is the same design as the supers but deeper. Some beekeepers will keep particularly vigorous colonies of bees on two brood boxes or sometimes a brood box and a super known as a "brood and a half".

Floor

There was a time when we used solid wooden floors because this helped keep the bees warm in winter. Then we got Varroa which is a parasite which feeds on the larvae. However they fall off the larvae and in doing so they fall to the floor of the hive. If it is a solid floor to the hive then the varroa climb back into the brood box to feast on the brood. By having a mesh floor the varroa fall through the floor and out of the hive. The other argument for a mesh floor is that it aids ventilation and hence there is less chance of the hive getting damp inside.

Entrance

The entrance in the summer is a gap the full width of the hive in which the bees are constantly moving as they bring in pollen and nectar. In the autumn there are fewer bees going in and out of the hive. Also there are stores of honey which the wasps would love to get hold of. At this point we put in an entrance block which slots in to the entrance and restricts the size of the entrance. Many blocks can be rotated to give a larger or smaller gap. The advantage of a small entrance is that the guard bees which repel wasps have a much narrower entrance to patrol. Imagine a football match where the goal mouth was the full width of the pitch! A narrower entrance also helps keep the heat in the hive.

Mouse Guard

Once the pollen is no longer coming in it is the time to put the mouse guards on the hive. The aim of these is to make certain that no mice get in and feed on honey and bees! In my case I delay putting the mouse guards on earlier because the construction of the guard has a tendency to take the pollen out of the pollen basket from the bee's legs.

The risk of leaving it this late is that there may already be a mouse in there and perhaps you are locking it in. If you are doing a hive inspection a good sniff at the crown board when you first remove the lid may indicate a mouse is present - they have a very distinctive smell.

The guards which I use have small holes to nail them across the entrance. After using them for several years I seem to have holes in the hive wherever I want to nail the guard. To get round this problem I have drilled holes at each end of he guard to take a small screw. That should let me use the guard on those hives for many more years

Landing Board

This is not an essential part of the hive but one which I have always appreciated and I suspect so have my bees. It is simply a piece of wood the width of the hive and sticks forward about 50mm. Its advantage to you is that it gives you more opportunity to see the bees as they return to the hive so you can see what they are bringing in. For the bees they will find landing easier when returning on a milder winter day and not having to fly straight into a hole in the mouse guard.

Hive Stand

This is simply a stand which raised the hive up from the ground. The purpose is that the hive is away from the damp ground and this can be more signifiant for those using open mesh floors. The other advantage is that it saves you having to bend quite as far when inspecting the hive. The design of the hive stand varies significantly from a small pile of concrete building blocks or a couple of pallets to a proper wooden stand. Personally I prefer the concrete building blocks and if they are felt to be unsightly then build a wooden facade - a lot easier and cheaper than buying a wooden stand.

So which of the hives should I use?

BS National - This is probably the most popular in the UK. It is designed for the less prolific and more docile bees such as the Buckfastleigh bee. One of the reasons for its popularity is the act that a full super is not too heavy to lift. A BS Commercial super can be too heavy for many beekeepers. especially those of us not in our first youth.The sides are 460mm long (external dimensions) and the super is 150mm deep whilst the brood is 225mm deep.The frames are 432mm long though 38mm is the long lug at each end leaving 355mm wide comb (plus 1mm slack).The brood box can hold 63,000 cells on 12 frames which will be a lot of brood in the summer and a lot of food stores in the winter.

BS Commercial - This is a bigger hive and though it has the same footprint (460mm by 460m) the super is 162 mm deep and the brood box is 267mm deep. What adds to the weight is that the frames have shorter lugs and so the width of the comb increases to 406mm

WBC hive is the classic hive we expect to see. The pagoda like structure makes them attractive so garden centres often sell compost bins of the same external shape. They were invented by William Broughton Carr in 1890 and are effectively a small National Hive surrounded by the covers or "lifts". They are popular amongst garden designers but for the beekeeper they are quite difficult to use. For a full hive inspection you must remove most of the lifts then you start your inspection. At the end of the inspection all the lifts have to be put back in place all the time trying to knock the hive and disturb the bees as little as possible.The good news is that the frames of a National hive are compatible with a WBC hive so you could have a working WBC for show and the rest of your apiary could be Nationals.